Themotashaft ine hollow, ine yakanaka kupisa kupisa kuita uye inogona kusimudzira kureruka kwemota.Kare, shafts yemotokari yainyanya kusimba, asi nekuda kwekushandiswa kwemotokari shafts, kushushikana kwaiwanzoiswa pamusoro pepamusoro pemvura, uye kushushikana kwepakati kwaive kuduku. Zvinoenderana nekukotama uye torsional zvimiro zvezvinhu mechanics, iyo yemukati chikamu chemotashaft yakacherwa kunze zvakakodzera, uye dhayamita diki rekunze chete raidiwa kuwedzera chikamu chekunze. Iyo hollow shaft inogona kusangana nekuita kwakafanana uye kushanda seyakasimba shaft, asi huremu hwayo hunogona kudzikiswa zvakanyanya. Zvichakadaro, nekuda kwegomba remotashaft, kutonhora kwemafuta kunogona kupinda mukati memota shaft, kuwedzera nzvimbo yekupisa kupisa uye kugadzirisa kupisa kwekushisa. Pasi pemaitiro azvino e800V yakakwira-voltage nekukurumidza kuchaja, mukana wehollow mota shafts wakakura. Iyo yazvino nzira dzekugadzira dzehollow mota shafts dzinonyanya kusanganisira yakasimba shaft hollowing, welding, uye yakasanganiswa kuumbwa, pakati peiyo welding uye yakasanganiswa kuumbwa kunoshandiswa zvakanyanya mukugadzira.

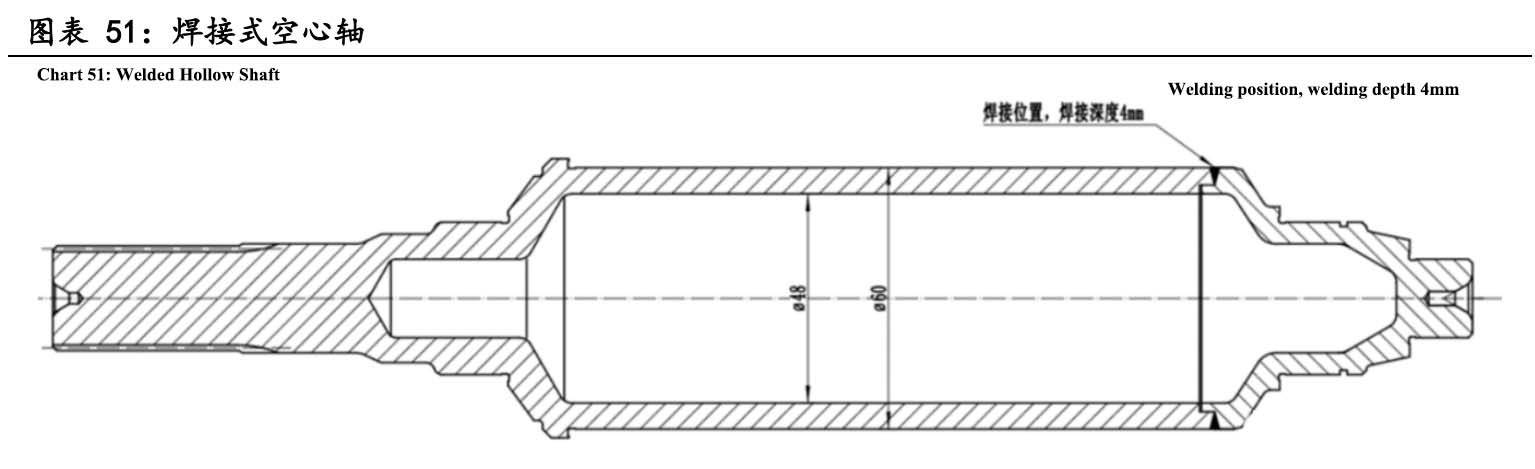

Iyo welded hollow shaft inonyanya kuwanikwa kuburikidza neextrusion kuumbwa kuti uwane yakatsikwa yemukati gomba re shaft, wozogadzirwa nemashini uye welded kuita chimiro. Nekuumbwa kweextrusion, shanduko yechimiro chegomba remukati ine chimiro chechigadzirwa uye simba rinodiwa zvinochengetwa zvakanyanya sezvinobvira. Kazhinji, iyo yakakosha madziro ukobvu wechigadzirwa unogona kugadzirwa pazasi 5mm. Welding midziyo inowanzo tora butt friction welding kana laser welding. Kana butt friction welding ikashandiswa, nzvimbo yejoint yebutt inowanzoita 3mm welding protrusion. Uchishandisa laser welding, kudzika kwewelding kunowanzo kuve pakati pe3.5 ne4.5mm, uye simba rewelding rinogona kuvimbiswa kuve rakakura kupfuura 80% ye substrate. Vamwe vatengesi vanogona kutowana pamusoro pe90% yesimba re substrate kuburikidza neakasimba maitiro ekudzora matanho. Mushure mekudzikiswa kwegomba shaft kwapera, zvinodikanwa kuita ultrasonic kana X-ray bvunzo pane iyo microstructure uye weld mhando yenzvimbo yewelding kuti ive nechokwadi chekuenderana kwechigadzirwa.

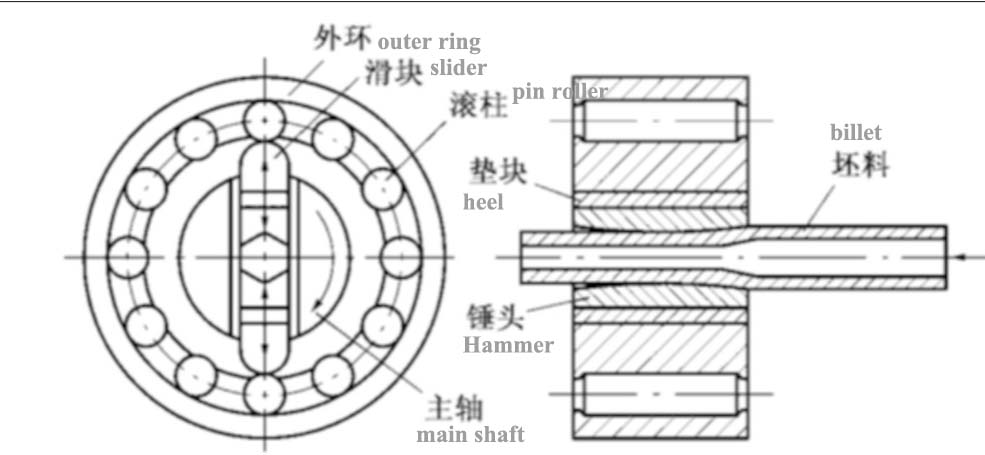

Iyo yakabatanidzwa inoumba hollow shaft inonyanya kuumbwa nemidziyo yekunze pane isina chinhu, ichigonesa chikamu chemukati kuti chiwane zvakananga gomba remukati reshaft. Parizvino, radial forging uye rotary forging inonyanya kushandiswa, uye michina yacho inonyanya kutengwa kunze kwenyika. Iyo radial forging yakajairwa nemidziyo yekambani yeFELLS, nepo kutenderera kwekugadzira kwakafanana nemidziyo yekambani yeGFM. Radial forging forming inowanzo wanikwa nekushandisa sando ina kana kupfuura symmetrical pafrequency inodarika mazana maviri nemakumi mana ekurova paminiti kuti iwane diki deformation yeyakashama uye yakananga maburi chubhu isina kuumbwa. Rotary forging forming inzira yekuronga zvakaenzana misoro yesando zhinji mudenderedzwa remabhii. Musoro wesando unotenderera uchitenderedza axis uchiita radial yakakwira-frequency forging pane iyo workpiece, ichidzikisa muchinjiko-chikamu saizi yebillet uye ichiwedzera axially kuti iwane workpiece. Kuenzaniswa neyechinyakare shafts yakasimba, mutengo wekugadzira weakasanganiswa akaumbwa shafts uchawedzera ne20%, asi huremu hwemotokari shafts hunowanzo kuderedzwa ne30-35%.

Nguva yekutumira: Sep-15-2023