1. Nhanganyaya kune Electric Motors

Mota yemagetsi mudziyo unoshandura simba remagetsi kuita simba remagetsi. Inoshandisa coil ine simba (kureva stator winding) kugadzira magineti inotenderera uye kuita pane rotor (senge tsindi keji yakavharwa aruminiyamu furemu) kugadzira torque yemagnetoelectric inotenderera.

Mota dzemagetsi dzakakamurwa kuita DC mota uye AC mota zvinoenderana neakasiyana masimba anoshandiswa. Mazhinji emotor ari musimba remagetsi ma AC motors, anogona kunge ari synchronous motors kana asynchronous motors (iyo stator magineti kumhanya kwemota haina kuchengetedza synchronous kumhanya nerotor kutenderera kumhanya).

Mota yemagetsi inonyanya kuve ne stator uye rotor, uye kutungamira kwesimba rinoshanda pawaya ine simba mune remagineti ine hukama negwara rezvino uye kutungamira kweiyo magineti induction line (magnetic field direction). Nheyo yekushanda yemotokari yemagetsi ndiyo mhedzisiro yesimba remagineti pasimba rinoshanda pane yazvino, zvichiita kuti mota itenderere.

2. Kuparadzaniswa kwemagetsi emagetsi

① Classification nekushanda magetsi ekupa

Zvinoenderana neakasiyana anoshanda masosi emagetsi emagetsi mota, anogona kukamurwa kuita DC mota uye AC mota. AC mota dzakakamurwa kuita imwe-chikamu mota uye matatu-chikamu mota.

② Kurongwa nechimiro uye nheyo yekushanda

Mota dzemagetsi dzinogona kukamurwa kuita DC mota, asynchronous mota, uye synchronous motors zvinoenderana nechimiro chavo uye musimboti wekushanda. Synchronous motors inogona zvakare kukamurwa kuita magineti echigarire synchronous mota, kusada synchronous mota, uye hysteresis synchronous mota. Asynchronous motors inogona kukamurwa kuita induction motors uye AC commutator mota. Induction motors inokamurwa kuita matatu-chikamu asynchronous mota uye shaded pole asynchronous motors. AC commutator motors zvakare yakakamurwa kuita imwe-chikamu mutsara inonakidza mota, AC DC mbiri chinangwa mota, uye zvinosemesa mota.

③ Yakakamurwa nekutanga uye maitiro ekushanda

Magetsi emagetsi anogona kukamurwa kuita capacitor akatanga single-phase asynchronous motors, capacitor inoshanda single-phase asynchronous motors, capacitor yakatanga single-phase asynchronous motors, uye kupatsanura chikamu chimwe-chikamu asynchronous motors zvinoenderana nekutanga uye kushanda modes.

④ Kurongwa nechinangwa

Mota dzemagetsi dzinogona kukamurwa kuita mota dzekutyaira uye dzinodzora mota zvinoenderana nechinangwa chadzo.

Magetsi emagetsi ekutyaira anopatsanurwazve kuita maturusi emagetsi (kusanganisira kuchera, kupukuta, kukwenenzvera, kutsveta, kucheka, nekuwedzera maturusi), mota dzemagetsi emidziyo yemumba (kusanganisira michina yekuwachisa, mafeni emagetsi, mafiriji, maair conditioner, marekodha, marekodha evhidhiyo, MaDVD player, vacuum cleaners, makamera, mabhomba emagetsi, mashavha emagetsi, nezvimwewo), uye mamwe madiki emuchina midziyo (inosanganisira maturusi emuchina madiki akasiyana, michina midiki, zvekurapa, zviridzwa zvemagetsi, nezvimwewo).

Kudzora mota dzakakamurwa kuita stepper mota uye servo mota.

⑤ Kurongwa ne rotor chimiro

Zvinoenderana nechimiro cherotor, mota dzemagetsi dzinogona kukamurwa kuita cage induction motors (yaimbozivikanwa se squirrel cage asynchronous motors) uye ronda rotor induction motors (yaimbozivikanwa semaronda asynchronous motors).

⑥ Classified kuburikidza kushanda nokukurumidza

Mota dzemagetsi dzinogona kukamurwa kuita mota dzinomhanya, dzakaderera-kumhanya mota, dzinogara dzichimhanya mota, uye dzinochinja-mhanya mota zvinoenderana nekumhanya kwadzo.

⑦ Kurongwa nefomu rekudzivirira

a. Vhura mhando (senge IP11, IP22).

Kunze kwechimiro chinodiwa chekutsigira, mota haina kuchengetedzwa kwakakosha kune inotenderera uye inorarama zvikamu.

b. Yakavharwa mhando (yakadai seIP44, IP54).

Izvo zvinotenderera uye zvipenyu zvikamu mukati memota casing zvinoda kuchengetedzwa kwemuchina kudzivirira kusangana netsaona, asi hazvitadzise kufefetera zvakanyanya. Dziviriro mota dzakakamurwa kuva anotevera marudzi zvichienderana neavo akasiyana mhepo uye kudzivirira zvimiro.

ⓐ Mesh chivharo mhando.

Iwo mavhuriro ekufemesa emota akafukidzwa nemafukidziro ane perforated kudzivirira zvikamu zvinotenderera uye zvipenyu zvemotor kuti zvisasangana nezvinhu zvekunze.

ⓑ Kudonhedza mvura.

Chimiro chemotor vent chinogona kudzivirira kudonha zvinwiwa kana solids kubva yakananga mukati memota.

ⓒ Uchapupu hwepasplash.

Chimiro chemotor vent chinogona kudzivirira zvinwiwa kana zvimedu kuti zvipinde mukati memotor mune chero nzira mukati meiyo yakatwasuka angle renji ye100 °.

ⓓ Yakavharwa.

Chimiro chemota casing chinogona kudzivirira kuchinjika kwemahara kwemhepo mukati nekunze kwecasing, asi haidi kuvharwa kwakazara.

ⓔ Isingapindi mvura.

Chimiro chemota casing chinogona kudzivirira mvura ine imwe dzvinyiriro kuti ipinde mukati memota.

ⓕ Kusapinda mvura.

Kana mota ichinyudzwa mumvura, chimiro chemota casing chinogona kudzivirira mvura kupinda mukati memota.

ⓖ Diving style.

Iyo mota yemagetsi inogona kushanda mumvura kwenguva yakareba pasi peyakayerwa mvura yekumanikidza.

ⓗ Chiratidzo chekuputika.

Chimiro chemotokari casing yakakwana kudzivirira kuputika kwegasi mukati memotokari kubva pakuendeswa kunze kwemotokari, zvichiita kuti kuputika kwegasi rinopisa kunze kwemotokari. Official account "Mechanical Engineering Literature", injiniya gasi chiteshi!

⑧ Inokamurwa neventilation uye kutonhora nzira

a. Kuzvitonhodza.

Magetsi emagetsi anovimba chete nemwaranzi yepasi uye kuyerera kwemhepo kwechisikigo kutonhora.

b. Self cooled fan.

Motokari yemagetsi inofambiswa nefeni inopa mweya unotonhorera kutonhorera pamusoro kana mukati memota.

c. Iye fani akatonhorerwa.

Iyo fan inopa mhepo inotonhorera haifambisirwe neiyo mota yemagetsi pachayo, asi inotyairwa yakazvimirira.

d. Pipeline ventilation type.

Mhepo inotonhorera haiunzwe zvakananga kana kuburitswa kunze kwemota kana kubva mukati memota, asi inounzwa kana kuburitswa kubva mumotokari kuburikidza nemapombi. Mafeni ekufemesa pombi anogona kuve ega fan yatonhodzwa kana imwe fan yakatonhodzwa.

e. Kutonhora kwemvura.

Magetsi emagetsi anotonhodzwa nemvura.

f. Yakavharwa yedunhu gasi kutonhora.

Iyo yepakati kutenderera yekutonhodza mota iri munharaunda yakavharwa inosanganisira mota uye inotonhorera. Iyo yekutonhodza inobata kupisa kana ichipfuura nemumota uye inoburitsa kupisa kana ichipfuura nemuinotonhorera.

g. Kutonhorera kwepamusoro uye kutonhora kwemukati.

Iyo yekutonhodza iyo isingapfuuri nemukati memotor conductor inodaidzwa kutonhora kwepamusoro, nepo inotonhorera inopfuura nemukati memotor conductor inodaidzwa kutonhora kwemukati.

⑨ Kurongwa nekuisa chimiro fomu

Iyo yekuisa fomu yemagetsi emagetsi inowanzomiririrwa nemakodhi.

Iyo kodhi inomiririrwa nechidimbu IM yekumisikidzwa kwenyika,

Tsamba yekutanga muIM inomiririra kodhi yemhando yekuisa, B inomiririra kuisirwa kwakachinjika, uye V inomiririra kumisa kwakamira;

Diji rechipiri rinomiririra kodhi yemhando, inomiririrwa nenhamba dzechiArab.

⑩ Kukamurwa nedanho rekudzivirira

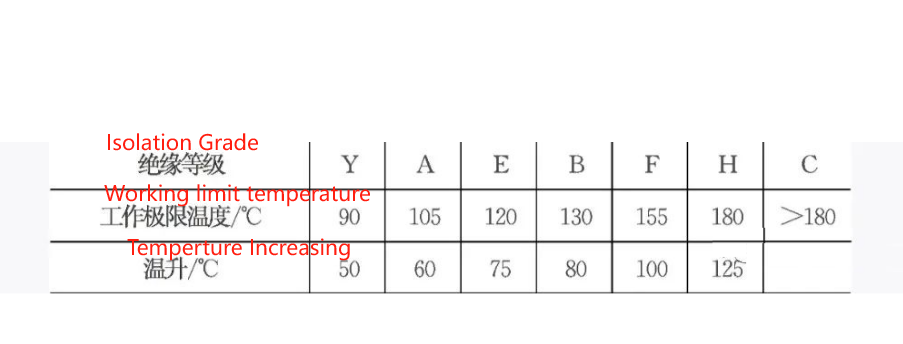

A-level, E-level, B-level, F-level, H-level, C-level. Iyo insulation level classification yemotor inoratidzwa mutafura pazasi.

⑪ Yakakamurwa zvinoenderana neyakayerwa maawa ekushanda

Inoenderera, inopindirana, uye yenguva pfupi yekushanda system.

Inoenderera Duty System (SI). Iyo mota inovimbisa kushanda kwenguva refu pasi peiyo yakatemerwa kukosha inotsanangurwa pane nameplate.

Nguva pfupi yekushanda maawa (S2). Iyo mota inogona kungoshanda kwenguva shoma yenguva pasi peiyo yakatemerwa kukosha inotsanangurwa pane nameplate. Kune marudzi mana ehurefu hwenguva yekushanda kwenguva pfupi: 10min, 30min, 60min, uye 90min.

Intermittent working system (S3). Iyo mota inogona kushandiswa chete pakati pepakati uye nguva nenguva pasi peiyo yakatemerwa kukosha inotsanangurwa pane nameplate, inoratidzwa sechikamu chegumi maminetsi kutenderera. Somuenzaniso, FC = 25%; Pakati pavo, S4 kune S10 ndeye akati wandei anopindirana anoshanda masisitimu ekushanda pasi pemamiriro akasiyana.

9.2.3 Kukanganisa kwakajairika kwemagetsi emagetsi

Magetsi emagetsi anowanzosangana nezvikanganiso zvakasiyana-siyana panguva yekushanda kwenguva refu.

Kana iyo torque yekufambisa pakati pechibatanidza uye inoderedza yakakura, gomba rekubatanidza pane flange pamusoro rinoratidza kupfeka kwakanyanya, izvo zvinowedzera kukwana gap rekubatanidza uye kunotungamirira kune kusagadzikana kwekutengesa torque; Kupfeka kwenzvimbo yekutakura kunokonzerwa nekukuvadzwa kwemotokari shaft kutakura; Pfeka pakati pemisoro yeshaft uye keyways, etc. Mushure mekuitika kwezvinetso zvakadaro, nzira dzechinyakare dzinonyanya kutarisa kugadzirisa welding kana machining mushure mekugadzira brashi, asi zvose zvine zvimwe zvinokanganisa.

Kushushikana kwekupisa kunogadzirwa nepamusoro tembiricha yekugadzirisa welding haigone kubviswa zvachose, iyo inowanzo pfugama kana kuputsika; Zvisinei, kuputika kwebhurashi kunogumira nehupamhi hwekuputira uye kunowanzoita kusvuura, uye nzira mbiri dzinoshandisa simbi kugadzirisa simbi, iyo isingagoni kuchinja "yakaoma kune yakaoma" hukama. Pasi pekuita kwakasanganiswa kwemasimba akasiyana-siyana, zvicharamba zvichikonzera kupfeka zvakare.

Nyika dzemazuva ano dzekuMadokero dzinowanzoshandisa zvinhu zvepolymer composite senzira dzekugadzirisa kugadzirisa nyaya idzi. Iko kushandiswa kwezvinhu zvepolymer kugadzirisa hakukanganise welding yekupisa kushushikana, uye ukobvu hwekugadzirisa hauna kugumira. Panguva imwecheteyo, zvigadzirwa zvesimbi zviri muchigadzirwa hazvina kuchinjika kutora maitiro uye kuzunguzika kwemidziyo, kudzivirira mukana wekupfekazve, uye kuwedzera hupenyu hwesevhisi yemidziyo yemidziyo, kuchengetedza nguva yakawanda yekudzikira kwemabhizinesi uye. kugadzira kukosha kukuru kwehupfumi.

(1) Kukanganisa chiitiko: Iyo mota haigone kutanga mushure mekubatana

Zvikonzero uye maitiro ekubata ndeaya anotevera.

① Stator winding wiring error - tarisa wiring uye gadzirisa kukanganisa.

② Vhura dunhu mune stator mhepo, pfupi dunhu kudzika, kuvhurika dunhu mumhepo yeronda rotor mota - tarisa painotadza uye uibvise.

③ Yakawandisa mutoro kana yakanamatira nzira yekufambisa - tarisa nzira yekufambisa uye mutoro.

④ Vhura dunhu munharaunda yerotor yeronda rotor mota (yakashata kusangana pakati pebhurashi neinotsvedza mhete, yakavhurika dunhu mu rheostat, kusabatana kwakashata mumutungamiri, nezvimwewo) - tsvaga nzvimbo yakavhurika yedunhu uye gadzirisa.

⑤ Simba rekushandisa magetsi rakaderera - tarisa chikonzero uye ubvise.

⑥ Simba rekupa chikamu kurasikirwa - tarisa dunhu uye dzosera iyo matatu-chikamu.

(2) Kukanganisa chiitiko: Tembiricha yemota inokwira zvakanyanya kana kuputa

Zvikonzero uye maitiro ekubata ndeaya anotevera.

① Kuremerwa kana kutanga kakawanda - kuderedza mutoro uye kuderedza nhamba yekutanga.

② Kurasikirwa kwechikamu panguva yekushanda - tarisa dunhu uye dzorera nhatu-chikamu.

③ Stator winding wiring kukanganisa - tarisa wiring uye uigadzirise.

④ The stator winding yakadzikwa, uye kune pfupi dunhu pakati pekutendeuka kana nhanho - tsvaga pasi kana pfupi nzvimbo yedunhu uye gadzirisa.

⑤ Cage rotor mhepo yakaputsika - tsiva rotor.

⑥ Kushaikwa kwechikamu chekushanda kweronda rotor mhepo - tsvaga pakanganisa uye gadzirisa.

⑦ Kukakavadzana pakati pe stator uye rotor - Tarisa mabheji uye rotor ye deformation, kugadzirisa kana kutsiva.

⑧ Kufefetera kwakashata - tarisa kana mhepo isina kuvharwa.

⑨ Voltage yakawandisa kana yakaderera - Tarisa chikonzero uye chibvise.

(3) Mhosva chiitiko: Kuwedzeredza mota vibration

Zvikonzero uye maitiro ekubata ndeaya anotevera.

① Rotor isina kuenzana - kuyera chiyero.

② Pulley isina kuenzana kana yakabhenda shaft yekuwedzera - tarisa uye gadzirisa.

③ Iyo mota haina kuenderana neyekuremerwa axis - tarisa uye gadzirisa axis yeyuniti.

④ Kuiswa kwakashata kwemota - tarisa kuisirwa uye nheyo screws.

⑤ Kamwe kamwe kuwandisa - kuderedza mutoro.

(4) Mhosva chiitiko: Kunzwika kusina kujairika panguva yekushanda

Zvikonzero uye maitiro ekubata ndeaya anotevera.

① Kupopotedzana pakati pe stator uye rotor - Tarisa mabhengi uye rotor ye deformation, kugadzirisa kana kutsiva.

② Mabheji akakuvadzwa kana asina mafuta - shandura uye chenesa mabhengi.

③ Motor chikamu kurasikirwa kushanda - tarisa yakavhurika yedunhu poindi uye gadzirisa.

④ Kudhumhana kweblade necasing - tarisa uye bvisa zvikanganiso.

(5) Mhosva chiitiko: Kumhanya kwemota kwakadzikira zvakanyanya kana iri pasi pemutoro

Zvikonzero uye maitiro ekubata ndeaya anotevera.

① Iyo magetsi emagetsi yakadzikira - tarisa magetsi emagetsi.

② Mutoro wakawandisa - tarisa mutoro.

③ Cage rotor mhepo yakaputsika - tsiva rotor.

④ Kubata kwakashata kana kusabatanidzwa kwechimwe chikamu cheboka rinomonereka rotor waya - tarisa kudzvanywa kwebhurashi, kubata pakati pebhurashi uye mhete inotsvedza, uye rotor mhepo.

(6) Mhosva chiitiko: Iyo mota casing inorarama

Zvikonzero uye maitiro ekubata ndeaya anotevera.

① Kudzika pasi kwakashata kana kupikisa kwepasi - Batanidza waya yepasi maererano nemirau kuti ubvise kukanganisa kwakashata kwepasi.

② Mamhepo anonyorova - anoomeswa kurapwa.

③ Kukuvara kwekudzivirira, kudhumhana kwekutungamira - Dip pendi kugadzirisa kusungirira, batanidzazve zvinotungamira. 9.2.4 Maitiro ekushanda kweMotor

① Usati wadimburwa, shandisa mweya wakadzvanywa kupeperetsa guruva pamusoro pemota woipukuta yakachena.

② Sarudza nzvimbo yekushanda yemotokari disassembly uye chenesa nzvimbo yepa-saiti.

③ Kujairana nemaitiro ezvimiro uye kugadzirisa tekinoroji zvinodiwa zvemagetsi mota.

④ Gadzirira maturusi anodiwa (kusanganisira maturusi akakosha) uye midziyo yekubvisa.

⑤ Kuti uwedzere kunzwisisa kukanganisa mukushanda kwemotokari, kuongorora kwekuongorora kunogona kuitwa kusati kwaitwa disassembly kana mamiriro achibvumira. Kuti izvi zviitike, mota inoedzwa nemutoro, uye tembiricha, ruzha, vibration, uye mamwe mamiriro echikamu chimwe nechimwe chemota anotariswa zvakadzama. Iyo voltage, ikozvino, kumhanya, nezvimwe zvinoedzwa zvakare. Zvadaro, mutoro wacho unobviswa uye imwe yakasiyana-siyana yekuongorora-yero yekuongorora inoitwa kuti ienzanise iyo isina-mutoro ikozvino uye isina-mutoro kurasikirwa, uye zvinyorwa zvinogadzirwa. Official account "Mechanical Engineering Literature", injiniya gasi chiteshi!

⑥ Cheka magetsi, bvisa waya yekunze yemota, uye chengeta zvinyorwa.

⑦ Sarudza yakakodzera voltage megohmmeter kuti uedze kudzivirira kudzivirira kwemota. Kuti uenzanise kukosha kwekudzivirira kwekudzivirira kwakayerwa panguva yekupedzisira kugadzirisa kuti uone mafambiro ekuchinja kwe insulation uye chimiro chekudzivirira chemota, iyo insulation resistance value inoyerwa patembiricha dzakasiyana inofanirwa kuchinjirwa kune imwe tembiricha, kazhinji ichishandurwa kuita 75 ℃.

⑧ Edzai chiyero chekutora K. Kana chiyero chekutora K> 1.33, chinoratidza kuti kuvhara kwemotokari hakuna kukanganiswa nehunyoro kana chiyero chekunyorova hachina kuoma. Kuti uenzanise neyakapfuura data, zvinodikanwawo kushandura chiyero chekutora chakayerwa pane chero tembiricha kune tembiricha yakafanana.

9.2.5 Kuchengetedza uye kugadziriswa kwemagetsi emagetsi

Kana injini ichimhanya kana kusashanda, kune nzira ina dzekudzivirira uye kubvisa zvikanganiso panguva yakakodzera, dzinoti, kutarisa, kuteerera, kunhuwa, uye kubata, kuve nechokwadi chekushanda kwakachengeteka kwemota.

(1) Tarisa

Cherechedza kana pane zvisizvo panguva yekushanda kwemotokari, iyo inonyanya kuratidzwa mumamiriro ezvinhu anotevera.

① Kana stator inotenderera ipfupi, chiutsi chinogona kuonekwa kubva mumotokari.

② Kana mota yakaremerwa zvakanyanya kana kupera chikamu, kumhanya kunononoka uye pachava nekuremedza "buzzing" ruzha.

③ Kana mota ichimhanya zvakajairika, asi ikaerekana yamira, twumoto twunogona kuoneka pakubatana kwakasununguka; Chiitiko chekufuridzirwa kwefusi kana kuti chikamu chiri kunamira.

④ Kana mota ichizunguzika zvine chisimba, inogona kunge iri nekuda kwekujairika kwechishandiso chekutapurirana, kusagadzika zvakanaka kwemota, mabhaudhi akasununguka, nezvimwe.

⑤ Kana paine kushanduka kwemavara, mavanga ekutsva, uye mavara echiutsi pane emukati mabatani uye makabatana emota, zvinoratidza kuti panogona kunge paine kupisa kwenzvimbo, kusabatana kwakashata pakubatanidza kondakita, kana mahwindi akatsva.

(2) Teerera

Iyo mota inofanirwa kuburitsa yunifomu uye chiedza "buzzing" ruzha panguva yakajairika kushanda, pasina chero ruzha kana yakakosha ruzha. Kana ruzha rwakawandisa ruchiburitswa, kusanganisira ruzha rwemagetsi, ruzha, ruzha rwemhepo, ruzha rwemuchina, etc., inogona kunge iri precursor kana chiitiko chekusashanda zvakanaka.

① Kune emagetsi ruzha, kana mota ikaburitsa ruzha uye runorema, panogona kunge paine zvikonzero zvakati wandei.

a. Mhepo yemhepo pakati pe stator ne rotor haina kuenzana, uye inzwi rinoshanduka kubva kumusoro kusvika pasi nekamwe nguva yepakati pakati pekurira kwepamusoro uye pasi. Izvi zvinokonzerwa nekutakura kupfeka, izvo zvinoita kuti stator uye rotor zvisave zvakanyanya.

b. Iyo yechitatu-chikamu ikozvino haina kuenzana. Izvi zvinokonzerwa nekudzika kwakashata, kupfupika kwedunhu, kana kusabatana kwakashata kwematatu-chikamu chinomonereka. Kana ruzha rusina kujeka, zvinoratidza kuti mota yakaremerwa zvakanyanya kana kupera chikamu.

c. Lose iron core. Kudedera kwemota panguva yekushanda kunoita kuti mabhaudhi ekugadzirisa esimbi musimboti asununguke, zvichiita kuti silicon simbi yesimbi yesimbi simbi isunungure uye ibudise ruzha.

② Kutakura ruzha, inofanirwa kuongororwa nguva zhinji panguva yekushanda kwemota. Iyo yekutarisa nzira ndeyekutsikirira imwe mugumo wescrewdriver uchitarisana nenzvimbo inokwirisa yekutakura, uye imwe magumo iri padyo nenzeve kuti inzwe ruzha rwekubereka ichimhanya. Kana tambo ichishanda zvakanaka, ruzha rwayo ruchava ruzha runoenderera uye rudiki, pasina kuchinjika kweurefu kana kukwesha kwesimbi. Kana manzwi anotevera akaitika, anoonekwa seasina kujairika.

a. Ikoko kune "kuzununguka" kunonzwika apo kutakura kuri kushanda, iyo inonzwika yesimbi yesimbi, inowanzokonzerwa nekushayikwa kwemafuta mukutakura. Iyo inotakura inofanira kuparadzaniswa uye kuwedzerwa nehuwandu hwakakodzera hwemafuta ekuzora.

b. Kana pane "creaking" inonzwika, inzwi rinoitwa apo bhora rinotenderera, rinowanzokonzerwa nekuomeswa kwemafuta ekuzora kana kushaya mafuta. Chiyero chakakodzera chegirizi chinogona kuwedzerwa.

c. Kana paine "kudzvanya" kana "creaking" ruzha, irwo ruzha rwunogadzirwa nekufamba kusingaite kwebhora mukutakura, kunokonzerwa nekukuvadzwa kwebhora mukutakura kana kushandiswa kwenguva refu kwemota. , uye kuomeswa kwegirisi yekuzora.

③ Kana iyo nzira yekufambisa uye dhiraivha inoburitsa inoenderera kwete kuchinjika manzwi, anogona kubatwa nenzira dzinotevera.

a. Periodic "popping" inonzwika inokonzerwa nemajoini emabhandi asina kuenzana.

b. Periodic "thumping" inzwi rinokonzerwa nekubatana kwakasununguka kana pulley pakati pemashafts, pamwe chete nemakiyi akasakara kana makiyi.

c. Ruzha rwekudhumhana rusina kuenzana rwunokonzerwa nemhepo inodhumhana nevhavha yefeni.

(3) Kunhuwa

Nekunhuwa kunhuhwirira kwemota, zvikanganiso zvinogonawo kuzivikanwa uye kudzivirirwa. Kana kunhuhwirira kwakakosha kwependi kunowanikwa, kunoratidza kuti kupisa kwemukati kwemotokari kwakanyanyisa; Kana kunhuhwirira kwakasimba kunopisa kana kutsva kunowanikwa, zvinogona kunge zvakakonzerwa nekuputsika kwechidzitiro chekudzivirira kana kupisa kwemhepo.

(4) Bata

Kubata tembiricha yezvimwe zvikamu zvemota zvinogonawo kuona chikonzero chekusashanda zvakanaka. Kuchengetedza kuchengetedzwa, kumashure kweruoko kunofanira kushandiswa kubata zvikamu zvakapoteredza zvemotokari casing uye mabheji kana uchibata. Kana tembiricha yakashata ikaonekwa, panogona kunge paine zvikonzero zvakawanda.

① Kutadza kufema zvakanaka. Zvakadai senge fan dechment, yakavharika madhiri emhepo, nezvimwe.

② Kuwandisa. Kukonzera kuwandisa ikozvino uye kupisa kweiyo stator mhepo.

③ Dunhu pfupi pakati pe stator windings kana matatu-chikamu ikozvino kusaenzana.

④ Kakawanda kutanga kana mabhureki.

⑤ Kana tembiricha yakatenderedza bearing yakanyanya, inogona kukonzerwa nekutakura kukuvara kana kushaikwa kwemafuta.

Nguva yekutumira: Oct-06-2023