Zvinhu zvinokanganisa kushandiswa kwesimbi zvakanyanya

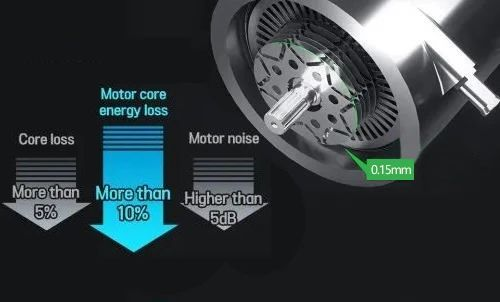

Kuti tiongorore dambudziko, tinofanira kutanga taziva dzidziso dzinokosha, dzichatibatsira kunzwisisa. Chekutanga, tinofanira kuziva pfungwa mbiri. Imwe ndeyekuchinjana kwemagnetization, iyo, muchidimbu, inoitika mukati mesimbi yetransformer uye mumazino e stator kana rotor emota; Imwe ndiyo rotational magnetization property, iyo inogadzirwa ne stator kana rotor joke yemota. Kune zvinhu zvakawanda zvinotanga kubva pamapoinzi maviri uye zvinoverenga kurasikirwa kwesimbi kwemota zvichibva pahunhu hwakasiyana zvichienderana nenzira yepamusoro yekugadzirisa. Kuedza kwakaratidza kuti silicon steel sheets inoratidza zvinotevera pasi pe magnetization yehunhu huviri:

Kana density yemagnetic flux iri pasi pe1.7 Tesla, kurasikirwa kwehysteresis kunokonzerwa nerotation magnetization kwakakura kupfuura uko kunokonzerwa ne alternating magnetization; Kana iri yakakwira kupfuura 1.7 Tesla, zvakapesana ndizvo zvazviri. Magnetic flux density yemota yejoko inowanzo kuve pakati pe1.0 ne1.5 Tesla, uye kurasikirwa kwakafanana kwe rotational magnetization hysteresis kwakakura ne45 kusvika 65% kupfuura kurasikirwa kwe alternating magnetization hysteresis.

Ehe, mhedziso dziri pamusoro apa dzinoshandiswawo, uye handina kuzvisimbisa pachangu. Pamusoro pezvo, kana simba remagineti riri musimbi inochinja, magetsi anokonzerwa mariri, anonzi eddy current, uye kurasikirwa kunokonzerwa nawo kunonzi eddy current losses. Kuti kuderedze kurasikirwa kwesimbi inoyerera, injini yesimbi inoyerera kazhinji haigone kugadzirwa kuita block yakazara, uye inounganidzwa neaxial nesimbi inoputirwa kuti isafambise mvura inoyerera. Fomura chaiyo yekuverenga yekushandiswa kwesimbi haizove yakaoma pano. Fomura yekutanga uye kukosha kwekuverenga kweBaidu iron consumption kuchave kwakajeka. Inotevera ongororo yezvinhu zvakakosha zvinokanganisa kushandiswa kwesimbi yedu, kuitira kuti munhu wese agonewo kuenderera mberi kana kudzokera shure anzwisise dambudziko iri mumashandisirwo einjiniya anoshanda.

Mushure mekukurukura zviri pamusoro apa, sei kugadzirwa kwestamping kuchikanganisa kushandiswa kwesimbi? Hunhu hwekuita kwepunching hunonyanya kutsamira pamhando dzakasiyana dzemichina yepunching, uye hunosarudza nzira yekucheka inoenderana uye huwandu hwekumanikidza zvichienderana nezvinodiwa zvemhando dzakasiyana dzemaburi nemakomba, nokudaro zvichiita kuti nzvimbo dzine kumanikidzwa kwakadzika dzive pedyo nemucheto welamination. Nekuda kwehukama huripo pakati pekudzika nechimiro, inowanzo kanganiswa nemakona akapinza, kusvika pakuti kumanikidzwa kwakakwira kunogona kukonzera kurasikirwa kwakakosha kwesimbi munzvimbo dzine kumanikidzwa kwakadzika, kunyanya mumipendero yakareba yekucheka mukati mechikamu chelamination. Kunyanya, inowanzoitika munzvimbo yealveolar, iyo inowanzova nzvimbo yekutsvagisa mukuita kwekutsvaga chaiko. Mapepa esimbi esilicon akaderera anowanzo tsanangurwa nehukuru hwezviyo. Kukanganisa kunogona kukonzera maburrs ekugadzira uye kutsemura shear pamucheto wepasi wepepa, uye kona yekurova inogona kukanganisa zvikuru saizi yemaburrs nenzvimbo dzekuchinja. Kana nzvimbo ine kushushikana kwakakwira ichienda pamwe chete nenzvimbo yekuchinja kwemucheto kusvika mukati mechinhu chacho, chimiro chezviyo munzvimbo idzi chichachinja zvinoenderana, kumonyoroka kana kutyoka, uye kureba kwakanyanya kwemuganhu kuchaitika pamwe chete nedivi rekubvaruka. Panguva ino, huwandu hwezviyo munzvimbo ine kushushikana munzvimbo yekuchekwa huchawedzera zvisingadzivisike, zvichikonzera kuwedzera kwakafanana kwekurasikirwa kwesimbi munzvimbo iyi. Saka, panguva ino, zvinhu zviri munzvimbo ine kushushikana zvinogona kuonekwa sechinhu chinorasikirwa zvakanyanya chinowira pamusoro pe lamination yakajairika pamucheto we impact. Nenzira iyi, constant chaiyo yezvinhu zvemucheto inogona kuzivikanwa, uye kurasikirwa chaiko kwemucheto we impact kunogona kuonekwa zvakare uchishandisa modhi ye iron loss.

1. Kupesvedzera kweAnnealing Process pakurasikirwa nesimbi

Mamiriro ekurasikirwa kwesimbi anonyanya kuwanikwa mumapepa esimbi esilicon, uye kushushikana kwemakemikari nekupisa kunokanganisa mapepa esimbi esilicon nekuchinja kwehunhu hwawo chaihwo. Kuwedzera kushushikana kwemakemikari kuchaita kuti pave nekuchinja mukurasikirwa kwesimbi. Panguva imwe chete, kuwedzera kwekupisa kwemukati memota kuchaitawo kuti pave nematambudziko ekurasikirwa nesimbi. Kutora matanho anoshanda ekubvisa kushushikana kwemakemikari kuchava nemhedzisiro inobatsira pakuderedza kurasikirwa kwesimbi mukati memota.

2. Zvikonzero zvekurasikirwa zvakanyanya mumabasa ekugadzira

Mapepa esimbi esilicon, sezvinhu zvikuru zvinoshandisa magineti zvemota, ane simba guru pakushanda kwemota nekuda kwekutevedzera zvinodiwa pakugadzira. Pamusoro pezvo, mashandiro emapepa esimbi esilicon emhando imwe chete anogona kusiyana kubva kune vagadziri vakasiyana. Pakusarudza zvinhu, kuedza kunofanira kuitwa kusarudza zvinhu kubva kune vagadziri vesimbi vesilicon vakanaka. Pazasi pane zvimwe zvinhu zvakakosha zvakakanganisa kushandiswa kwesimbi zvakambosangana nazvo kare.

Shiti yesimbi yesilicon haina kunyungudutswa kana kurapwa zvakanaka. Dambudziko rerudzi urwu rinogona kuonekwa panguva yekuedzwa kwemashiti esimbi yesilicon, asi havasi vese vagadziri vemota vane chinhu ichi chekuedza, uye dambudziko iri hariwanzo zivikanwa zvakanaka nevagadziri vemota.

Kudzivirira kwakakuvara pakati pemachira kana mapfupi pakati pemachira. Dambudziko iri rinowanzoitika panguva yekugadzira simbi. Kana kumanikidzwa panguva yekunamatira simbi kwakanyanya, zvichikonzera kukuvara kwekudzivirira pakati pemachira; Kana kuti maburi akakura zvakanyanya mushure mekubaya, anogona kubviswa nekupukuta, zvichikonzera kukuvara kukuru kwekudzivirira pamusoro pekubaya; Mushure mekunge simbi yapera, goko harina kutsetseka, uye nzira yekuisa faira inoshandiswa; Neimwe nzira, nekuda kwezvinhu zvakaita se stator bore isina kufanana uye kusabatana pakati pe stator bore nemuromo wechigaro chemuchina, kutendeuka kunogona kushandiswa kugadzirisa. Kushandiswa kwemaitiro aya ekugadzira mota nekugadzira mota kune simba guru pakushanda kwemota, kunyanya kurasikirwa nesimbi.

Kana uchishandisa nzira dzakadai sekupisa kana kupisa nemagetsi kupatsanura winding, zvinogona kukonzera kuti simbi iwedzere kupisa, zvichikonzera kudzikira kwesimba remagineti uye kukuvara kwekudzivirira mukati memachira. Dambudziko iri rinonyanya kuitika panguva yekugadzirisa winding nemota panguva yekugadzira nekugadzirisa.

Kubatanidza masimbi nezvimwe zvinhu zvinogona kukonzerawo kukuvara kwechinhu chinoputira masimbi pakati pemasimbi, zvichiwedzera kurasikirwa kwemvura inoyerera.

Kurema kwesimbi kusina kukwana uye kusimba kusina kukwana pakati pemachira. Mugumisiro wekupedzisira ndewekuti huremu hwesimbi hauna kukwana, uye mhedzisiro yakananga ndeyekuti simba remagetsi rinodarika kushivirira, nepo paine chokwadi chekuti kurasikirwa kwesimbi kunodarika mwero wezvinodiwa.

Kupenda kuri papepa resimbi resilicon kwakakora zvakanyanya, zvichiita kuti dunhu remagineti rinyanye kuzara. Panguva ino, hukama huripo pakati pemagetsi asina mutoro nemagetsi hwakakombama zvakanyanya. Ichi chinhu chakakoshawo mukugadzirwa nekugadzirisa mapepa esimbi esilicon.

Munguva yekugadzira nekugadzirisa masimbi esimbi, kurongeka kwesimbi yesimbi yesilicon steel punching uye shearing surface attachment kunogona kukuvara, zvichikonzera kuwedzera kwekurasikirwa kwesimbi pasi pesimba remagnetic induction rimwe chete; Kune mota dzinoshanduka-shanduka, kurasikirwa kwesimbi kwakawedzerwa kunokonzerwa nemaharmonics kunofanirawo kufungwa nezvako; Ichi chinhu chinofanira kufungwa nezvacho zvizere mukugadzira.

Pamusoro pezvinhu zvataurwa pamusoro apa, kukosha kwekugadzirwa kwesimbi yemota kunofanirwa kubva pakugadzirwa kwayo uye kugadziriswa kwesimbi yesimbi, uye zvese zvinofanirwa kuitwa kuti ive nechokwadi chekuti kukosha kwedzidziso kunoenderana nemutengo chaiwo. Makombama ehunhu anopiwa nevatengesi vezvinhu zvakajairwa anoyerwa uchishandisa nzira yeEpstein square coil, asi kutungamira kwemagnetization yezvikamu zvakasiyana mumota kwakasiyana, uye kurasikirwa uku kwesimbi inotenderera hakugone kufungwa nezvako parizvino. Izvi zvinogona kutungamira kune kusawirirana kwakasiyana pakati pemitengo yakaverengerwa neyakayerwa.

Nzira dzekuderedza kurasikirwa kwesimbi mukugadzira mainjiniya

Kune nzira dzakawanda dzekuderedza kushandiswa kwesimbi muinjiniya, uye chinonyanya kukosha ndechekugadzirisa mushonga kuti uenderane nemamiriro ezvinhu. Ehe, hazvisi zvekushandisa simbi chete, asiwo nezvezvimwe zvinorasikirwa. Nzira yakakosha ndeyekuziva zvikonzero zvekurasikirwa kwesimbi yakawanda, zvakaita sehuwandu hwemagineti, huwandu hwakawanda hwema frequency, kana kuwanda kwenzvimbo. Ehe, nenzira yakajairika, kune rumwe rutivi, zvakakosha kusvika pachokwadi pedyo sezvinobvira kubva kudivi rekufananidzira, uye kune rumwe rutivi, maitiro acho anosanganiswa netekinoroji kuderedza kushandiswa kwesimbi yakawedzerwa. Nzira inonyanya kushandiswa ndeyekuwedzera kushandiswa kwesimbi yesilicon yakanaka, uye zvisinei nemutengo, simbi yesuper silicon inounzwa kunze inogona kusarudzwa. Ehe, kuvandudzwa kwetekinoroji itsva dzinotungamirirwa nesimba remuno kwakatungamirawo kukura kuri nani mukumusoro nepasi. Makambani esimbi emuno ari kutangawo zvigadzirwa zvesimbi zvesilicon. Genealogy ine mhando yakanaka yezvigadzirwa zvemamiriro akasiyana ekushandisa. Heano nzira shoma dzakatwasuka dzekusangana nadzo:

1. Gadzirisa dunhu remagineti

Kugadzirisa magnetic circuit, kutaura chokwadi, ndiko kugadzirisa sine yemagnetic field. Izvi zvakakosha, kwete chete kune ma fixed frequency induction motors. Variable frequency induction motors uye synchronous motors zvakakosha. Pandaishanda muindasitiri yemichina yemachira, ndakagadzira mamota maviri ane mashandiro akasiyana kuderedza mitengo. Ehe, chinhu chakakosha kwaive kuvapo kana kusavapo kwematanda akakombama, izvo zvakakonzera kusagadzikana kwe sinusoidal hunhu hwemhepo ine gap magnetic field. Nekuda kwekushanda nekumhanya kwakanyanya, kurasikirwa kwesimbi kunokonzera chikamu chikuru, zvichikonzera mutsauko mukuru mukurasikirwa pakati pemamota maviri. Pakupedzisira, mushure mekuverenga zvishoma, mutsauko wekurasikirwa kwesimbi yemota pasi pe control algorithm wakawedzera nekanopfuura kaviri. Izvi zvinoyeuchidzawo munhu wese kubatanidza ma control algorithms pakugadzira ma variable frequency speed control motors zvakare.

2.Deredza magineti akawandisa

Kuwedzera kureba kwesimbi iri pakati kana kuwedzera nzvimbo yemagnetic conductivity ye magnetic circuit kuderedza magnetic flux density, asi huwandu hwesimbi inoshandiswa mumota hunowedzera zvinoenderana;

3. Kuderedza ukobvu hwesimbi kuti uderedze kurasikirwa kwemagetsi anokonzerwa

Kutsiva machira esimbi esilicon akaputirwa nekupisa nemashizha esimbi esilicon akaputirwa nechando kunogona kuderedza ukobvu hwemachira esimbi esilicon, asi machira esimbi matete anowedzera huwandu hwemachira esimbi uye mitengo yekugadzira mota;

4. Kugamuchira mapepa esimbi esilicon akaputirwa anotonhora ane simba remagineti rakanaka kuderedza kurasikirwa nehysteresis;

5. Kugamuchira chivharo chesimbi chinopisa chinoshanda zvakanyanya;

6. Kurapa kupisa uye tekinoroji yekugadzira

Kushushikana kwasara mushure mekugadzirisa machipisi esimbi kunogona kukanganisa zvakanyanya kurasikirwa kwemota. Pakugadzirisa machira esimbi esilicon, nzira yekucheka uye kumanikidzwa kwekucheka zvine simba guru pakurasikirwa kwesimbi. Kucheka uchitevedza nzira yekumonera yesimbi yesilicon uye kuita kurapwa kwekupisa pasimbi yesilicon kunogona kuderedza kurasikirwa ne10% kusvika 20%.

Nguva yekutumira: Mbudzi-01-2023