Iyomotamugodhi hauna chinhu, une simba rakanaka rekuparadza kupisa uye unogona kukurudzira kurema kwemota.Kare, migero yemota yaive yakasimba zvakanyanya, asi nekuda kwekushandiswa kwemigero yemota, kushushikana kwaiwanzoiswa pamusoro pemugero, uye kushushikana pakati pemugero kwaive kudiki. Zvichienderana nehunhu hwekukombama uye hwekutenderera kwemakanika emidziyo, chikamu chemukati chemugeromotaMugodhi wakachekwa zvakanaka, uye dhayamita diki yekunze yaidiwa kuti chikamu chekunze chiwedzere. Mugodhi une hollow unogona kusangana nekushanda kwakafanana negodhi rakasimba, asi huremu hwawo hunogona kuderedzwa zvakanyanya. Panguva iyi, nekuda kwekuchekwa kwemotaMugodhi, oiri inotonhodza inogona kupinda mukati memugodhi wemota, zvichiwedzera nzvimbo yekudzima kupisa uye zvichivandudza kushanda zvakanaka kwekudzima kupisa. Pasi pemaitiro aripo ekuchaja nekukurumidza kwe800V, mukana wekuisa magonhi emota wakakura. Nzira dzekugadzira magonhi emota dzine shaft dzinosanganisira kudzika kwemugodhi wakasimba, kusveta, uye kugadzira kwakabatana, pakati pazvo kusveta nekugadzira kwakabatana zvinoshandiswa zvakanyanya mukugadzira.

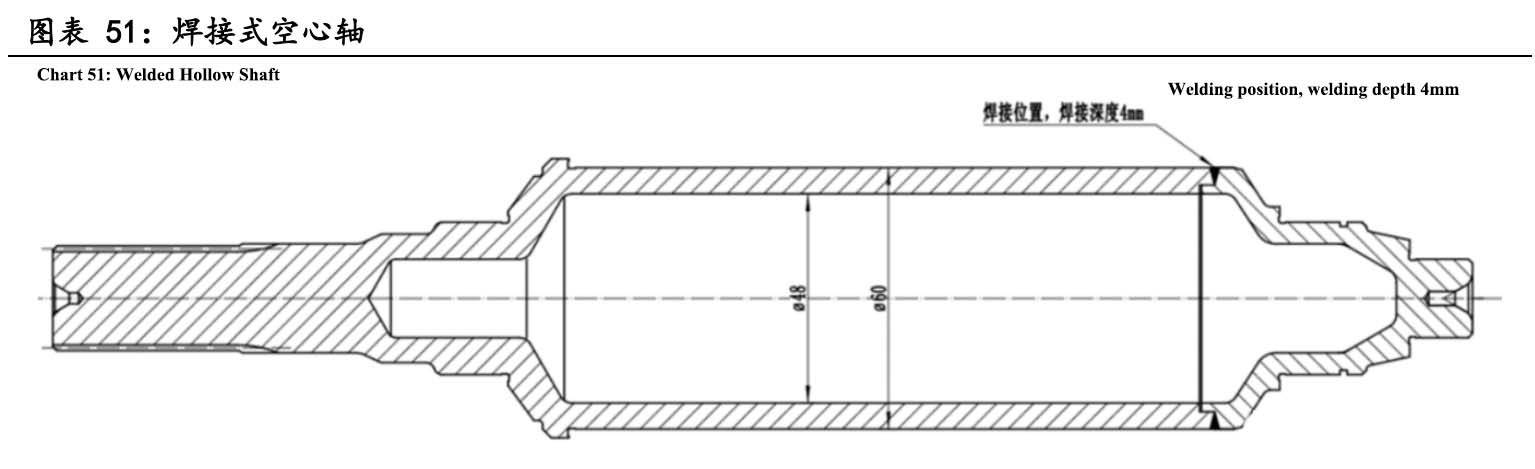

Mugodhi une hollow shaft unonyanya kuwanikwa kuburikidza nekugadzira extrusion kuti uwane gomba remukati rine matanho, uye wobva wagadzirwa ne machine uye washved kuita chimiro. Nekuumbwa kwe extrusion, kushanduka kwechimiro chegomba remukati nechimiro chechigadzirwa uye zvinodiwa nesimba zvinochengetwa zvakanyanya sezvinobvira. Kazhinji, ukobvu hwemadziro echigadzirwa hunogona kugadzirwa pasi pe 5mm. Midziyo yekushongedza inowanzo shandiswa kusanganisa butt friction welding kana laser welding. Kana butt friction welding ikashandiswa, nzvimbo yebutt joint inowanzo kuve inenge 3mm welding protrusion. Uchishandisa laser welding, kudzika kwewelding kunowanzova pakati pe 3.5 ne 4.5mm, uye simba rewelding rinogona kuvimbiswa kuti rakakura kupfuura 80% ye substrate. Vamwe vatengesi vanogona kutosvika pamusoro pe 90% yesimba re substrate kuburikidza nematanho ekudzora maitiro akaomarara. Mushure mekunge welding ye hollow shaft yapera, zvinodikanwa kuita ultrasound kana X-ray bvunzo pa microstructure uye weld quality ye weld area kuti ive nechokwadi chekuti chigadzirwa chakafanana.

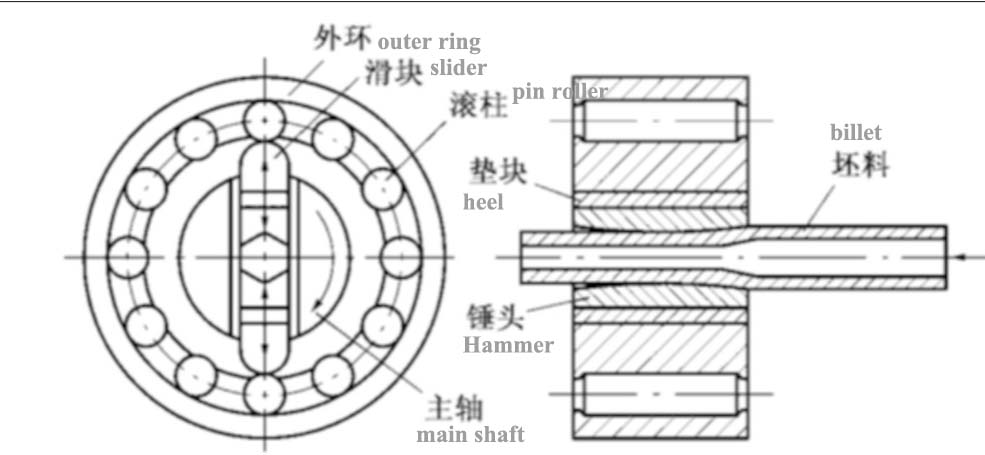

Mugodhi wepaburi wakabatanidzwa unonyanya kugadzirwa nemidziyo yekunze iri paburi, zvichiita kuti chikamu chemukati chikwanise kuwana zvakananga buri remukati remugodhi. Parizvino, radial forging nerotary forging zvinonyanya kushandiswa, uye michina inonyanya kutengwa kunze kwenyika. Radial forging inowanzoitwa nemidziyo yekambani yeFELLS, nepo rotary forging yakafanana nemidziyo yekambani yeGFM. Radial forging inowanzoitwa nekushandisa hammers ina kana kupfuura dzakafanana pahuwandu hwemabhuroko anopfuura 240 paminiti kuti iite deformation diki yeblank uye yakananga hollow tube blank forming. Rotary forging inzira yekuronga zvakaenzana hammer heads dzakawanda munzira yakatenderedza billet. Hammer head inotenderera yakatenderedza axis uku ichiita radial high-frequency forging paworkpiece, ichideredza saizi yecross-sectional yebillet uye ichitambanudzwa axially kuti iwane workpiece. Zvichienzaniswa netsika dzakasimba, mutengo wekugadzira we integrated formed hollow shafts uchawedzera neinenge 20%, asi huremu hwemotor shafts hunowanzo kudzikiswa ne30-35%.

Nguva yekutumira: Gunyana-15-2023